1. Purpose

The purpose of this Method Statement is to establish the rules & Safety requirements to be applied during the Excavation, Works are properly executed in accordance with Project Specifications and applicable standards.

2. Responsibilities of Project Team

2.1 Project Manager

Responsible for the project objectives by managing cost, time, scope, quality, and ensuring all project documentation, quality, and safety procedures are up to date and accessible.

2.2 Project Engineer / Civil Engineer

Responsible for overseeing all construction activities, also to make sure that all activities are followed by Project approved drawing, method of statement & Specification

2.3 Construction Supervisor / Foreman:

Responsible for ensuring work execution managing permits, conducting toolbox and enforcing safety measures and Find out the work executed by skilled labor or Technicians

2.4 Civil QC Inspector (QA/QC):

Responsible for inspecting all required activities before & After, following the inspection records.

2.5 Safety Officer:

Responsible for implementing safety compliance, conducting toolbox talks, making the proper barricading and signage, and immediately stopping and reporting any unsafe acts or conditions.

Safety officer will Follow the All HSE Requirement

Make sure that all labor and working staff used Proper PPE

3. Surveyor

- To verify the survey instruments working in good conditions and it has the valid certificates before stating the work

- Study the drawings thoroughly and make ensure all the drawings are approved by Project Team & Consultant.

- Check the pipeline routes and all road crossing shall be followed by Govt Approved benchmark

- Before start the survey works check any obstacles from existing underground utilities.

- Tripods shall be checked prior to fix survey instruments. And always handle the instrument with safe method and keep in good condition.

- To perform the survey, work as described method statements and approved procedures.

- Control points shall be checked periodically from Consultant Reference points to ensure control points are not disturbed.

- If any changes of values or coordinates variations arises inform to civil engineer / manager.

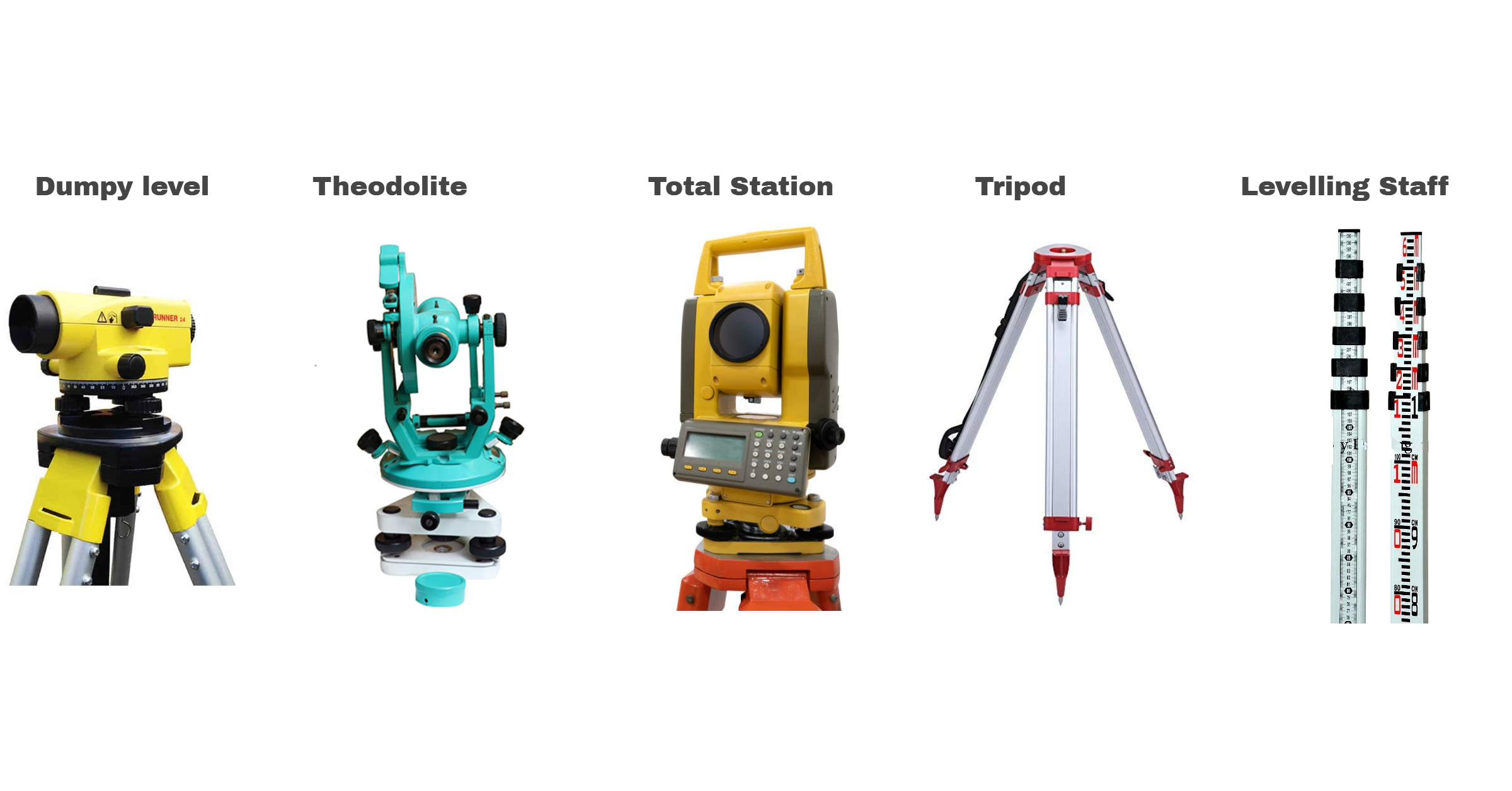

4. Required Equipment

- Levelling Instrument’s Such as (Dumpy level or Theodolite or Total Station), Tripod, Levelling Staff

- Excavator Machineries – Excavator, telescopic Handler etc.

- Hand Tools – shovels, picks, and axes etc.

- Safety Tools – Fire Extinguisher, Fire Blanket etc.

5. Survey & Marking

- Check the ground levels with a survey to understand the current height.

- Draw lines to show where excavation should happen, based on approved plans.

- Check for any underground cables or pipes using special equipment.

- Mark reference points to guide the depth and position of excavation.

6. Site Preparation

- Mark the area to be dug using white chalk or lime powder.

- Put up safety signs and fences around the site.

7. Excavation Process

- Start excavation using the required machineries.

- For deep holes, excavate in layer by layer

- Excavate to the required depth as per approved drawings.

- If water collects in the hole, use a pump to remove it.

- Move the excavated soil to the approved dumping area

8. Inspection and Verification

- A surveyor checks the depth and position of the excavation.

- An engineer checks that the excavated levels & sizes are as per drawings.

- QA / QC wil prepare the inspection report & Submit to the consultant approval.

- Consultant will check the site Inspection will be approved by consultant prior to start next activity.

- If any comments while site visit from consultant will be notified in the Inspection report accordingly that needs to be rectify.

- The inspection report will be documented & Maintain for future purpose