METHOD OF STATEMENT FOR BACKFILLING & COMPACTION WORK

PURPOSE

The purpose of this Method Statement is to establish the procedures and controls to be applied

during all backfilling and compaction works, including the selection of suitable fill material,

placement in layers, moisture adjustment, compaction, inspection, testing, and preparation of

the subgrade for ground slabs and external areas. This ensures that all backfilling and

compaction works are executed in accordance with Project Specifications, approved

drawings, and applicable standards, providing a stable and uniform foundation for subsequent

construction activities

MACHINARIES

a. Surveying Instruments

b. Compactor as per requirement

c. Excavator / Loader for placing fill

d. Water Tanker

e. Electric Tamping Rammer

• Equipment’s to be used at the job site shall include, but not limited to the following:

Manpower and Equipment

a. Construction Manager

b. Project Civil Engineer

c. Civil Construction Supervisor / Forman

d. Surveyor

e. Civil QC Inspector

f. Safety Officer

g. Operators for machineries

h. Helpers

METHOD OF STATEMENT FOR BACK FILLING & COMPACTION WORK

1. Preparation

- Excavations areas shall only be backfilled after permanent works are approved by the consultant.

- Required machineries inspected before starting the work

2. Backfilling

- Selected excavated material shall be used for backfilling where suitable.

- If excavated material is unsuitable, approved imported material shall be used.

- Complete installation of service ducts and pipework before placing fill and inspected by MEP Engineers If required

- Backfill shall be brought to levels above grade to allow for anticipated settlement.

- Backfill shall be sloped away from permanent structures for proper drainage.

3. Placement and Compaction

- The material is to be placed in layers within the effective range of compaction of the plant provided that the maximum loose (uncompacted) thickness of each layer does not exceed 200 mm.

- Adjust moisture content to ±3% of optimum moisture content.

- Compact each layer using approved compaction equipment until ≥ 95% maximum dry density is achieved.

- Every layer is properly backfilled & Compacted as per specification

- Compact each layer using suitable equipment until achieving the required density.

- Repeat process until the final required level is reached.

- Portable water to be used while compaction, also Ensure that uniform moisture distribution throughout compaction.

- No completed fill layer shall be covered by the next layer until it has been tested, inspected and approved by the Engineer.

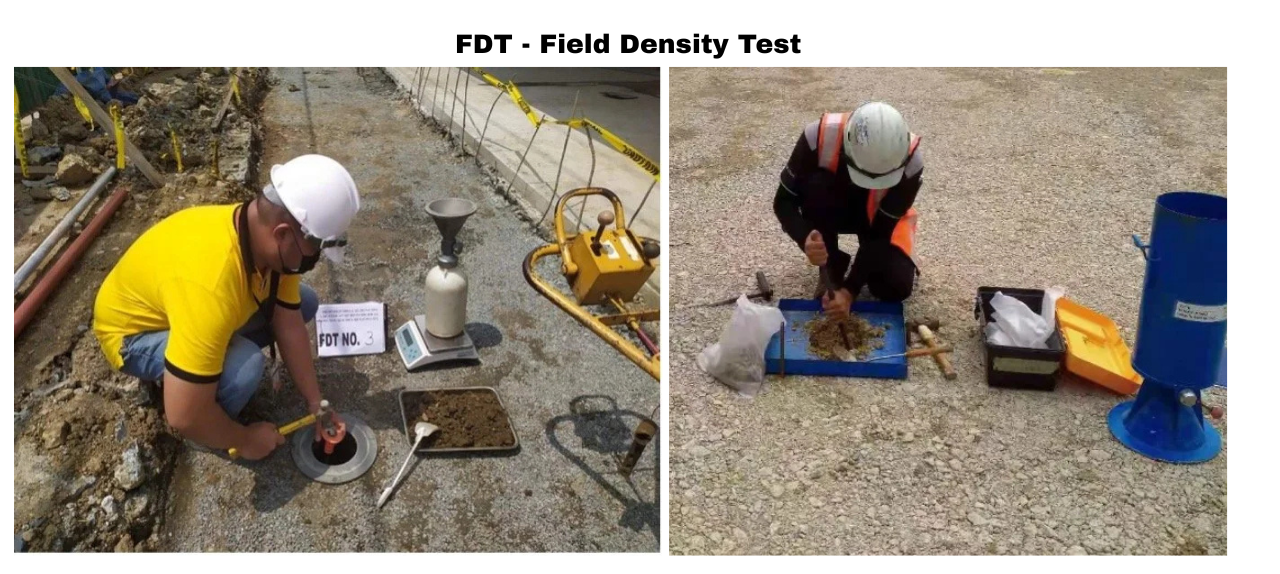

- After completion of the middle level of the backfilling and compaction Field Density Tests (FDT) will be conducted on site, and the results will be submitted to the consultant for approval

- For sloped areas, excavate benches to ensure horizontal deposition and uniform layering.

- After completion of Final level of the backfilling & Compaction Field Density Test (FDT) will be contacted at site & results will submit to the consultant for the approval

4. Quality Control & Testing

- Field density tests as per specification & Standards

- Finished surface level will be followed as per approved drawings

5. Health, Safety & Environment

- PPE to be worn at all times (helmets, vests, gloves, boots).

- Safe access and egress to excavation areas.

- Dust suppression and water management to protect the environment.

- Machinery to be operated only by trained personnel.