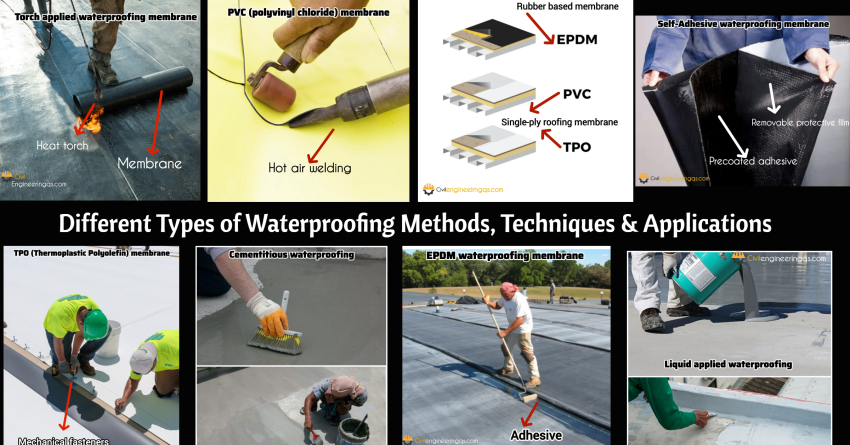

Waterproofing

Waterproofing is the process of protecting a building from water penetration and damage, It involves applying specialized materials that prevent water infiltration, Waterproofing is typically applied in areas such as roofs, bathrooms, and underground structures like footings, retaining walls, foundations, and water tanks, There are different types of waterproofing methods used on construction which based on project specification and condition.

These methods, categorized by material type, are described as follows:

- Torch applied Bituminous waterproofing membrane

- Self-adhesive Bituminous waterproofing membrane

- TPO roofing membrane (Thermoplastic Polyolefin)

- PVC roofing membrane (Polyvinyl chloride)

- EPDM membrane (Ethylene propylene diene terpolymer)

- Liquid Waterproofing Membranes

- Cementitious Waterproofing

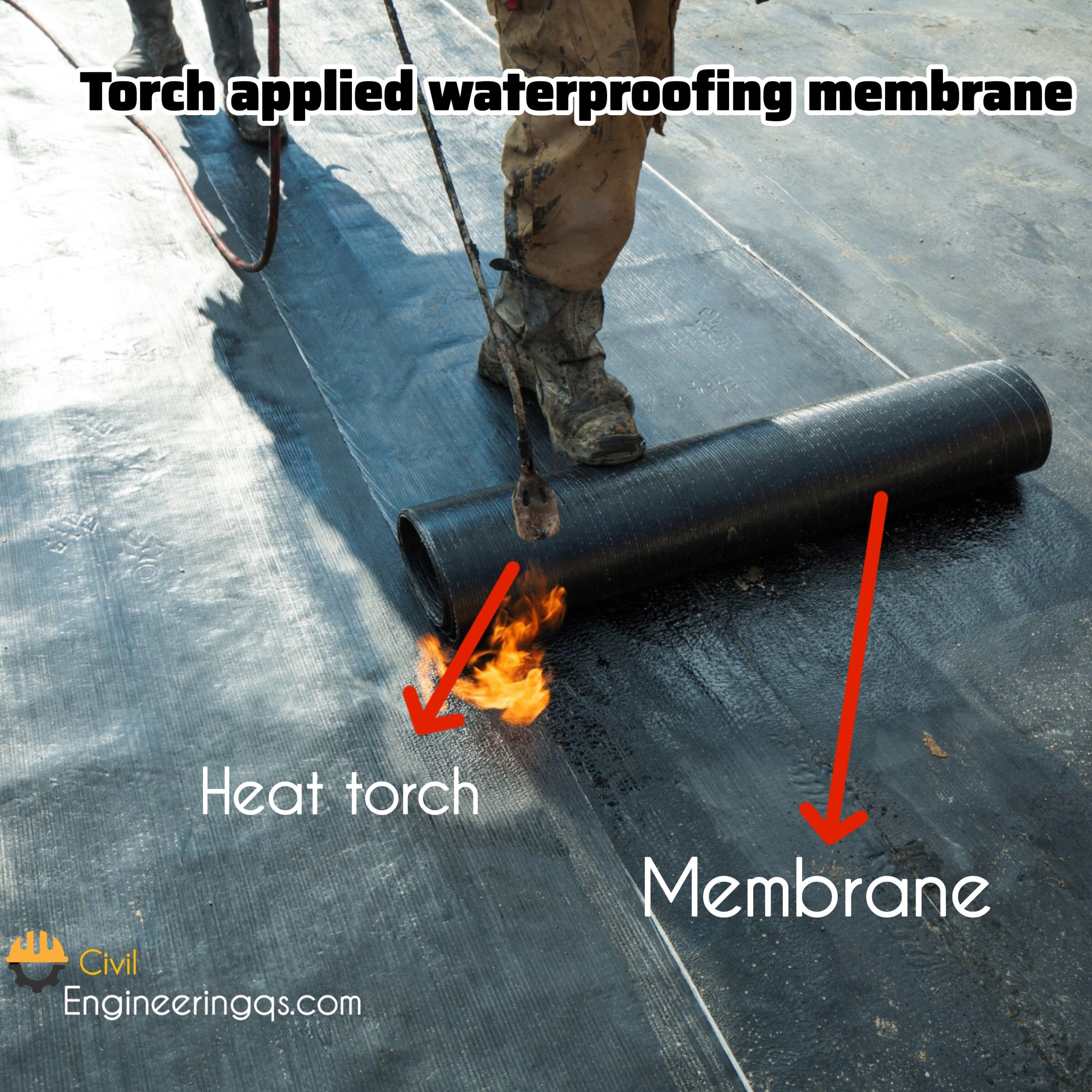

1. Torch applied Bituminous waterproofing membrane

- These membranes are manufacture by bitumen and are applied using a heat air torch, the heat melts the bitumen and its binding with primer

- In this method It is widely used in roofing, basements, foundations, & Bathrooms.

- There are two types of waterproofing bituminous membrane are used in torch applied waterproofing work which is APP & SBS membrane.

- APP– Atactic Polypropylene it is most suitable for Roof & Bathrooms

- SBS – Styrene-Butadiene-Styrene it is suitable for underground structure

Application (or) installation method

Surface preparation :- Surfaces clean from dust and repair cracks and any necessary repairs.

Primer Application : –

- Bituminous primer is applied over the surface using spray or roller.

- Based on project specification it will apply one layer or two layers, the second layer will be applied after properly dry the first layer.

- Approximately it will take 16 to 48 hours to dry based on environment condition.

Membrane application : – Membrane placed over the primer surface with heat air torch layer by layer Each layer is overlapped by another with an overlap width of at least 75-100mm

Also, membrane applied one layer or two layer using heat torch based on project specification

Water Test :- Perform a water test to ensure there are no leakages. The water should remain over the waterproofing for a minimum of 2 days.

2. Self-adhesive Bituminous waterproofing membrane

- Self-adhesive membranes are pre-coated with adhesive one side of the membrane roll.

- This is method is alternative method for heat torch applied membrane.

- These membranes easier to install and suitable for smaller projects or areas with limited access.

Application (or) installation method

Surface preparation: – surfaces clean from dust and repair cracks and any necessary repairs.

Primer Application: – Bituminous primer is applied over the surface, based on project specification it will apply one layer or two layers, the second layer will be applied after properly dry the first layer, approximately it will take 16 to 48 hours based on environment condition.

Membrane application: – Membrane placed over the primer surface with Removing the protective film from the adhesive side layer by layer, each layer is overlapped by another with an overlap width of at least 75-100mm

Also, in this type of membrane applied one layer or two layers using based on project specification

Water Test:- Perform a water test to ensure there are no leakages. The water should remain over the waterproofing for a minimum of 2 days.

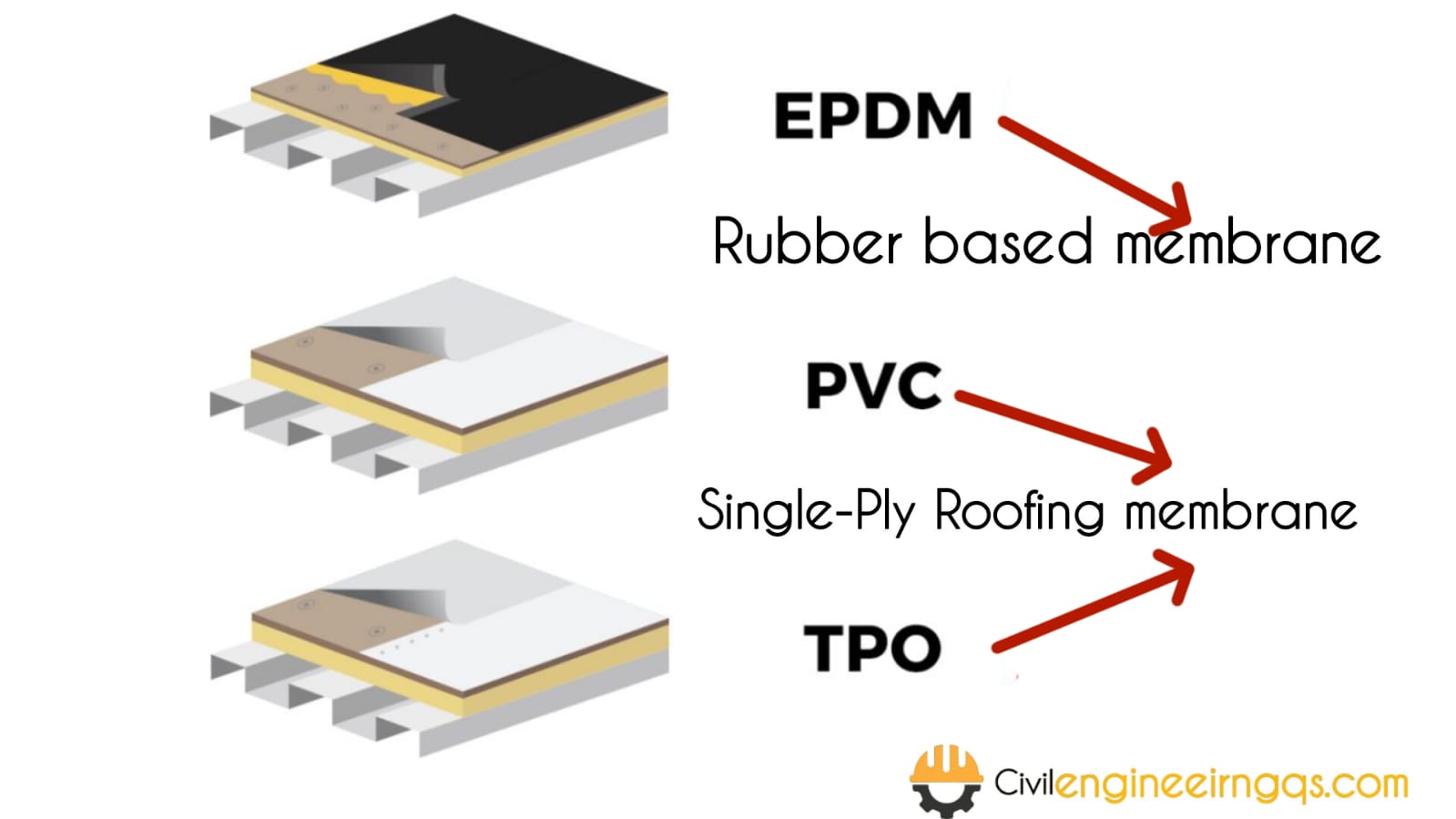

3. TPO Waterproofing membrane (Thermoplastic Polyolefin)

TPO membranes are a type of single-ply roofing membrane and its made by Thermoplastic Polyolefin, these membrane have an good durability, UV resistance, and flexibility also in this type of membrane is most suitable for Roof surfaces.

4. PVC Waterproofing membrane (Polyvinyl chloride)

PVC membranes are another type of single-ply roofing membrane. Which is made by Polyvinyl chloride. Also, it has good chemical resistance, durability, UV protection, and fire resistance. In this type of membrane is most suitable for Roof & underground surfaces such as basement, water tank, footing & retaining wall.

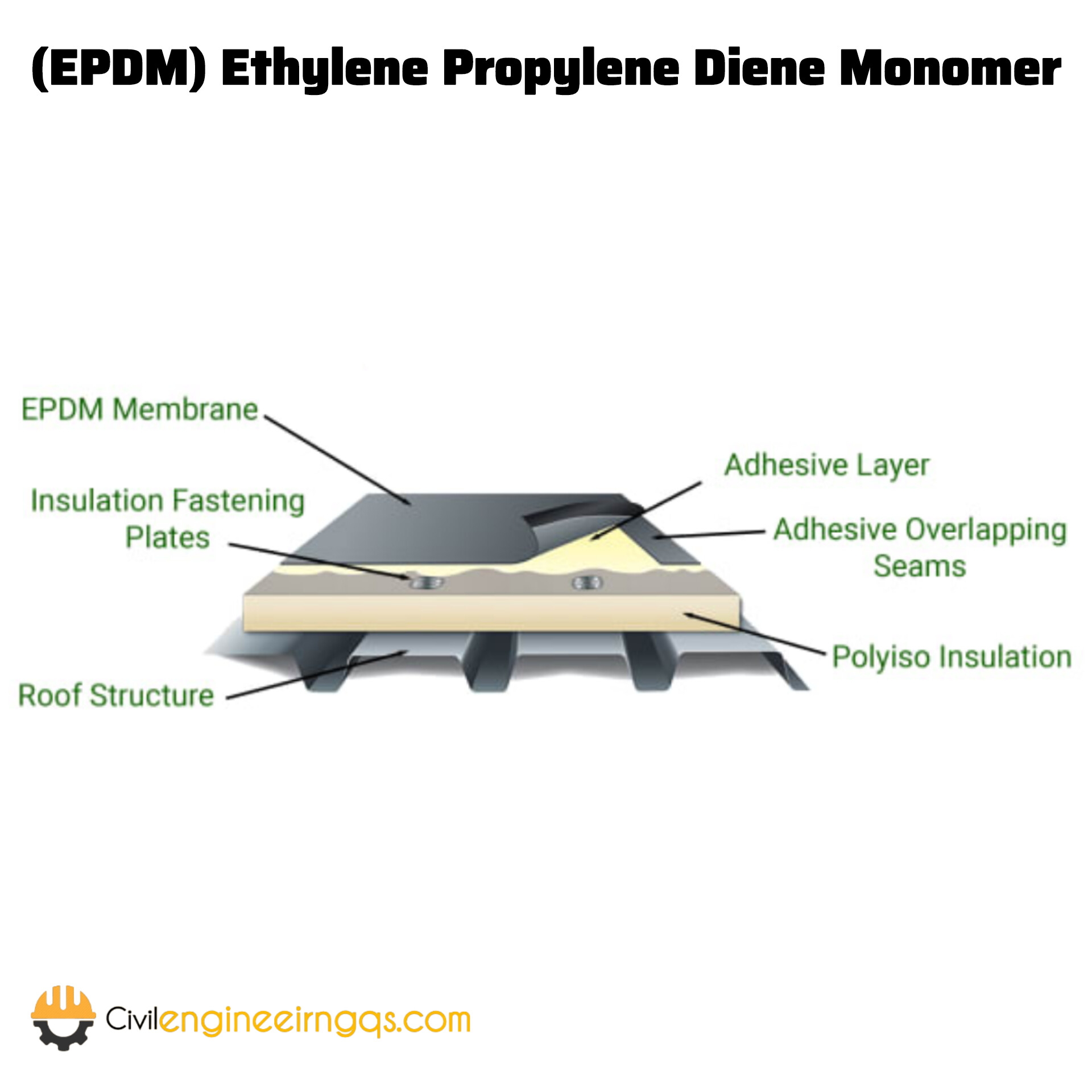

5. EPDM membrane (Ethylene propylene diene terpolymer)

EPDM membranes are rubber-based membranes which is made by Ethylene propylene diene terpolymer It is widely used for flat roofs. In this type of membrane also have an high elasticity, UV resistance, and durability.

Application method / Installation method for TPO, PVC & EPDM Membrane

In this TPO, PVC & EPDM membrane have a similar installation method

Surface preparation : – surfaces clean from dust and repair cracks and any necessary repairs.

After the surface preparation there are different method using for membrane installation

1. Mechanically Fastened

- In this method, the membrane is directly placed on the roof deck using screws or plates.

- This method is most suitable for areas with high winds, the fasteners help keep the membrane secure.

- Above the screw sealant use to cover the holes to avoid any water leakages & damages

2. Fully Adhered

In This method glue adhesive directly applied to the roof surface and membrane laid over the glue. It provides a smooth finish. and its works well for buildings with complex roof shapes.

3. Ballasted

In this method The membrane is placed on the roof and weighed down with heavy materials like gravel or pavers, this is less commonly used method

- Overlapping areas (typically 50 to 100 mm) are sealed using a hot-air welding machine.

- EPDM membranes typically use seam tape instead of hot-air welding for overlaps.

Water Test :- Perform a water test to ensure there are no leakages. The water should remain over the waterproofing for a minimum of 2 days

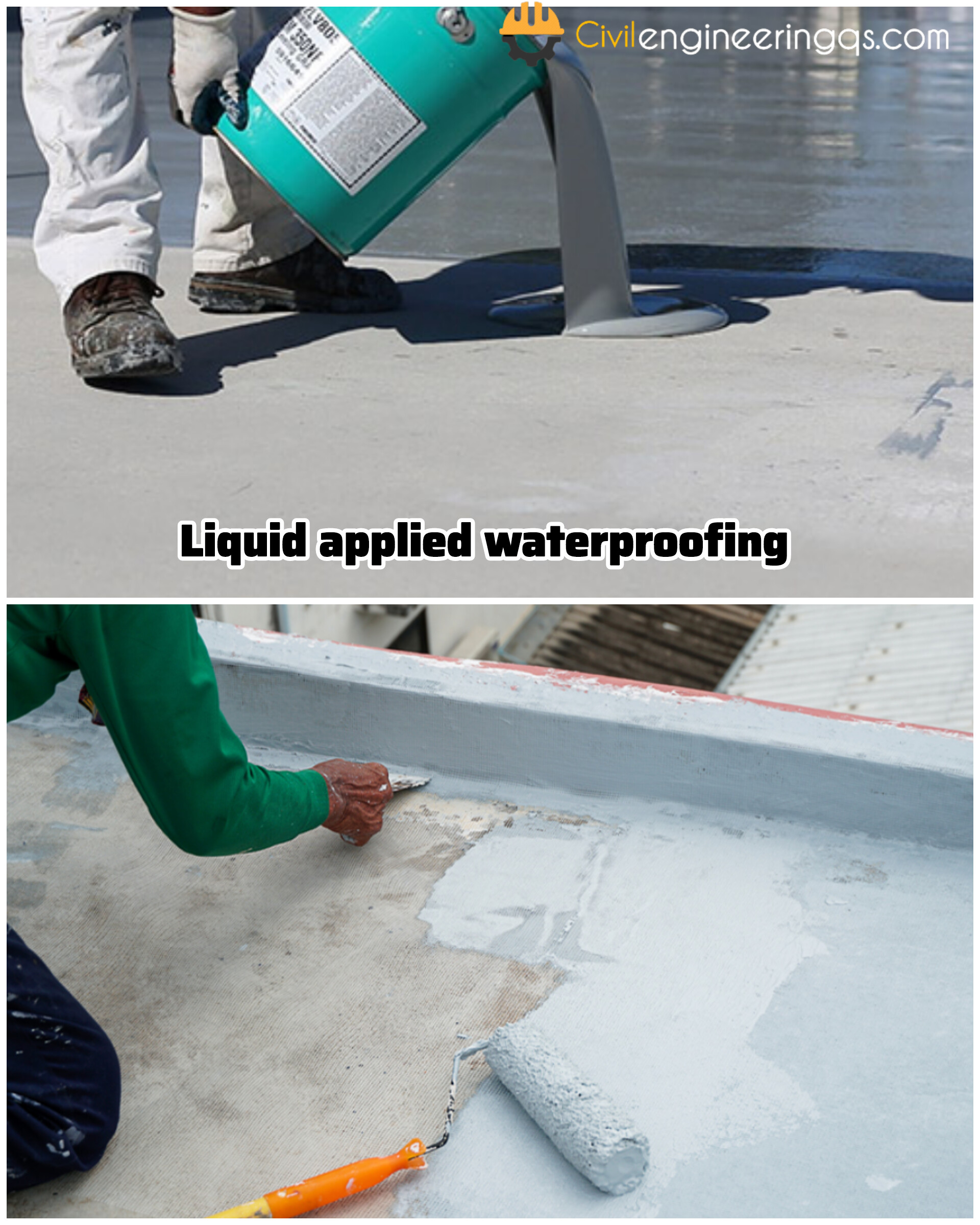

6. Liquid Waterproofing Membranes

- In this method, a liquid-based coating is applied over the surface to create a barrier against water penetration.

- Typically, acrylic, polyurethane, polymer, and bituminous-based coatings are used.

- This method is most commonly used in bathroom waterproofing works.

- It is also used for roofs and underground structures where intermediate waterproofing is required.

Application method

Surface preparation : – surfaces clean from dust and repair cracks and any necessary repairs.

After the surface preparation there are different method using for membrane installation

Primer Application (if Required) :-

- Primer is applied over the surface using a sprayer or roller.

- Depending on the project specifications, one or two layers of primer may be applied. The second layer is applied only after the first layer has dried properly.

- The drying time typically ranges from 16 to 48 hours, depending on environmental conditions.

Liquid Application

- The project-specified liquid-based membrane is applied over the primed surface using a roller or spray machine.

- One or two layers of liquid membrane are applied as per the project requirements, ensuring proper drying of the first layer before applying the second.

- The drying time for each layer is approximately 16 to 48 hours, depending on environmental conditions.

- Water Test: Perform a water test to ensure there are no leakages. The water should remain over the waterproofing for a minimum of 2 days

7. Cementitious Waterproofing

Cementitious waterproofing is a popular method for protecting concrete structures from water damage. It involves applying a cementitious coating to the surface, creating a durable and water-resistant barrier. These coatings are typically composed of Portland cement, fine aggregates, and a blend of polymers and additives.

In this type of waterproofing techniques is mot suitable for Bathroom, inside the water tanks, swimming pools, and sewage treatment plants.

Application method

Surface Preparation :- Ensure the surfaces clean from dust and repair cracks and any necessary repairs

Mixing the Cementitious Coating :- Prepare the mixture by combining the cement-based powder with water or a liquid polymer additive as specified as per project specification or manufacture standard.

Application of the Coating :-

- Apply the first coat using a brush, trowel, or roller, ensuring even coverage over the surface.

- Allow the first coat to dry for the recommended time (approximately its take 8 to 24 hours)

- Apply a second coat perpendicular to the first to ensure thorough coverage

Water Test :- Perform a water test to ensure there are no leakages. The water should remain over the waterproofing for a minimum of 2 days.